Reasons, Prevention and Treatment of Electrode Paste Hanging

Electrode paste hanging refers to the situation where the electrode paste blocks get stuck inside the electrode cylinder and are unable to descend, resulting in a large void in the middle of the electrode paste. When measuring the height of the electrode paste column during the occurrence of paste hanging, the height of the paste column remains unchanged for a long time. After a bit longer, a large amount of yellow smoke will emerge from the electrode cylinder. If not dealt with in a timely manner after paste hanging occurs, it may lead to the hard breakage or soft breakage of the electrode, and in extreme cases, even an explosion inside the electrode cylinder.

Reasons for Electrode Paste Hanging

- The electrode paste blocks are too large and get stuck in the rib plates of the electrode shell.

- The paste column is too high, and the temperature at the upper part of the electrode is too low to melt and sink the paste.

- During winter when the temperature is low, the heating elements are turned on and off intermittently.

- Large-sized foreign objects fall into the electrode cylinder, blocking the path of the electrode paste blocks.

In Inner Mongolia, China, the general temperature is relatively low. For instance, in a 33000kVA closed calcium carbide furnace of a certain calcium carbide factory, when the furnace was newly started in January, the coldest month of the year, considering that a higher electrode paste column would result in better strength of the sintered electrode, the height of the three-phase electrode paste columns was increased to more than 8 meters. As a result, paste hanging occurred in all three-phase electrodes. Two-phase electrodes were dealt with by cutting open the holding cylinders, while the other phase could not be processed. Eventually, yellow smoke emerged from the electrode cylinder, leading to a hard break of the electrode.

Prevention and Treatment Measures

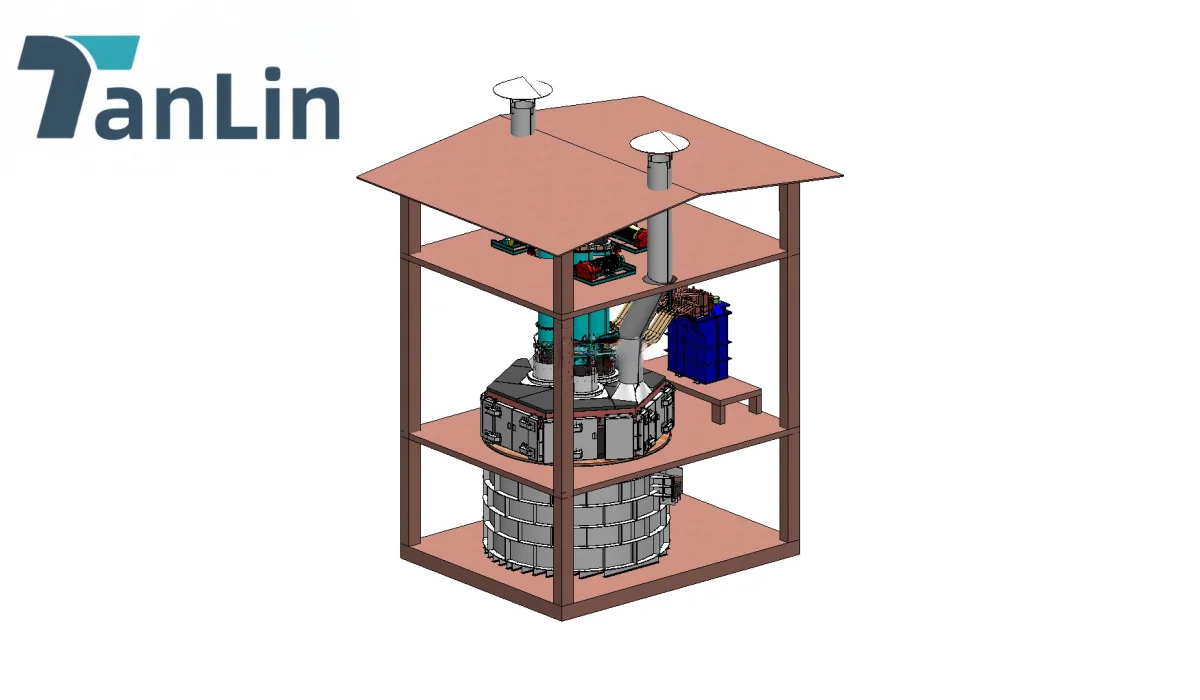

Tanlin’s electrode paste manufacturing process is excellent, which provides a solid foundation for the quality of the electrode paste. However, to prevent electrode paste hanging, the following measures should still be taken:

- Add electrode paste according to the height and particle size requirements specified in the process.

- When the temperature is low in winter, keep the heater running continuously and do not stop its operation.

- Cover the electrode cylinder to prevent foreign objects from falling in.

- Measure the height of the paste column once every 4 hours. If the height remains unchanged for 8 consecutive hours, immediate treatment is required.

- For treatment, one method is to tie a heavy object with a rope and use it to smash the stuck paste block to make it descend.

- Another method is to cut open the holding cylinder and the electrode cylinder with oxygen welding and then use a steel rod to push the paste block down.

By implementing these prevention and treatment measures and relying on Tanlin’s advanced manufacturing process, we can effectively reduce the occurrence of electrode paste hanging and ensure the stable operation of the production process.