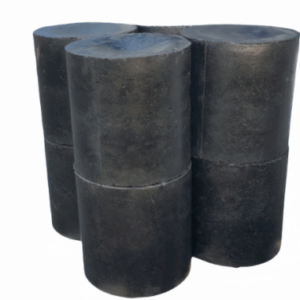

Electrode paste

Electrode paste

Electrode paste, also known as self-baking electrode or Soderberg paste, is made from bitumen as a diluent mixed with forged petroleum coke, electrocalcined anthracite and graphite powder. It is mainly used for the production of ferrosilicon, silicomanganese, ferrochrome, ferronickel, calcium carbide, yellow phosphorus and other smelting products.

His excellent self-baking performance can be adapted to the needs of multi-scenario industries. It is an indispensable and important material in the smelting of mineral heat furnace.

Tanlin carbon Electrode paste – An essential conductive material for mineral heating furnace

Product Features

- Outstanding electrical conductivity: Tanlin carbon Electrode Paste has high electrical conductivity, which can efficiently conduct the electric

current and provide a solid guarantee for the normal operation of the electric furnace. - Outstanding high-temperature resistance: even in the high-temperature environment of the furnace, Tanlin carbon electrode paste can still

maintain stable performance, and will not be softened or deformed due to high temperature. - Good sintering performance: With the operation of the furnace, Tanlin Trapezoidal Electrode Paste will gradually sinter to form a dense

conductive structure, which in turn improves the conductivity and strength. - Low impurity content: Tanlin Trapezoidal Electrode Paste has very few impurities, which can effectively avoid adverse effects on the furnace

production process and product quality. - Certain mechanical strength: In the process of installation and use, Tanlin trapezoidal electrode paste can withstand a variety of external

forces to ensure stability and reliability.

Product Parameter

Application scenario

- Mineral Heat Furnace: Tanlin carbon Electrode Paste can be used in Silico-manganese Furnace, Ferro-silicon Furnace, Nickel-iron Furnace,

Ferro-chrome Furnace, Calcium Carbide Furnace and so on. - Other types of electric furnaces: Besides mineral heat furnaces, Tanlin carbon electrode paste can also play a role in other types of electric

furnaces,such as calcium silicate furnaces, yellow phosphorus furnaces and so on. - Electrode maintenance: Tanlin carbon Electrode Paste is one of the important materials for electrode maintenance and replacement during the operation

of electric furnace.

Contact Us

There are many ranges of specifications and indicators for Ta electrode paste. What is the suitable product? It should be determined according to the model of the melting furnace of the customer, the operating process, and the product features. Please provide us with these information, and our engineers will develop a suitable solution for you. Whether you are our customer or not, we hope you can leave your information with us to discuss the development and use of Tanlin carbon electrode paste together.